SIC 3469

METAL STAMPINGS, NOT ELSEWHERE CLASSIFIED

This category includes establishments primarily engaged in manufacturing metal stampings and spun products, not elsewhere classified, including porcelain enameled products. Products of this industry include household appliance housings and parts, cooking and kitchen utensils, and other non-automotive job stampings.

NAICS Code(s)

339911 (Jewelry (including Precious Metal) Manufacturing)

332116 (Metal Stamping)

332214 (Kitchen Utensils, Pot and Pan Manufacturing)

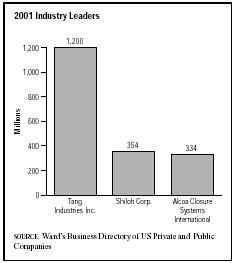

Tang Industries Inc. of Las Vegas led the industry with 2001 sales of almost $1.3 billion and 3,700 workers. Shiloh Corp. of Cleveland, Ohio, generated $354 million in sales and employed 3,200. Rounding out the top three industry leaders was Alcoa Closure Systems International of Indianapolis with sales of $334 million and 3,000 employees.

The largest portion of the industry stamps metal for motor homes, aviation, agricultural equipment, computers, electrical appliances, radios, televisions, kitchen appliances, and laundry equipment. Cooking and kitchen utensils, such as tea kettles, metal spoons, baking pans, and stainless steel mixing bowls, claim a distinct majority of the industry's product base.

Although computer-aided drafting and manufacturing tools had been used to great advantage in the metal-cutting industry, the related metal-forming industries had not used available software tools. Specialized software was being developed to add precision to the stamping process. Not only does computer software design improve stamping dies, it also can be interfaced with the machinery to tell the operator when the die is beginning to dull, or when the machine itself is beginning to malfunction.

The implementation of computer technology helps manufacturers to reduce costs throughout the spectrum of machining operations. For larger production lines, the area of specialty tooling is gaining importance as more companies cut costs and competition grows. With specialty tooling, several operations can be combined by using unique punch dies. Louver, countersink, embossing, lettering, and lance-and-form tools are gaining popularity as more industry leaders seek to improve product quality and cost through process redesign.

In particular, the mid-2000s saw innovations aimed toward cutting out steps in processing through in-press assembly techniques. Processes such as in-die contacting and multiple coil feeding improved cost, performance, and product quality over traditional rivet contacting and different stages in production and assembly.

According to the U.S. Department of Labor, Bureau of Labor Statistics, the forging and stamping industry as a whole was expected to employ 132,000 workers by 2012, a modest but steady growth of 1.5 percent annually.

Further Reading

"Adding Value." Appliance Manufacturer. May 2003.

Baker, Deborah J., ed. Ward's Business Directory of US Private and Public Companies. Detroit, MI: Thomson Gale, 2003.

U.S. Department of Labor, Bureau of Labor Statistics. Economic and Employment Projections. 11 February 2004. Available from http://www.bls.gov/news.release/ecopro.toc.htm .

Hoover's Company Fact Sheet. "Tang Industries, Inc." 2 March 2004. Available from http://www.hoovers.com .

"Magnesium Molding Gains Ground Globally." Plastics News. 24 June 2002.

Comment about this article, ask questions, or add new information about this topic: