SIC 2448

WOOD PALLETS AND SKIDS

This classification covers establishments primarily engaged in manufacturing wood or wood and metal combination pallets and skids.

NAICS Code(s)

321920 (Wood Container and Pallet Manufacturing)

The manufacture of wood pallets and skids is the largest segment of the wood container industry. Pallets are made of platforms that are specially designed to allow heavy crates and boxes to be easily moved by forklift. Pallets play an important role in the shipping, handling, and storage of a huge variety of materials in an equally vast array of industries.

Hardwood lumber, such as oak, was used for 67 percent of the wood in pallets at the turn of the twenty-first century. Manufacturers used a total of 4.41 billion board feet of hardwood lumber for pallets. Other wood materials used included stumpage, logs, and cants. Waste materials were sometimes used by pallet manufacturers to make fuel wood, bedding, pulp, or charcoal, among other products.

The biggest pallet users are the food, steel and metal, paper and printing, and chemical industries. The most common pallet produced is the flushed stringer, double-face, nonreversible type measuring 48 by 40 inches, which is most often used by supermarkets. Since the 1980s, technology has played an increasingly important role in the pallet and skid industry, contributing to both production and design improvements. Most pallet manufacturers still used hand-held nailers and semi-automated equipment in 1980. By the 1990s, however, fully automated assembly systems allowed two laborers to put together 1,200 pallets in a day, at least four times the rate of production that hand nailers allowed.

Industry leader PalEx Inc. of Houston, Texas, which generated 1998 sales of just under $320 million (up 43 percent from 1997), merged in 1999 with Munich, Germany-based International Food Container Organization (IFCO). PalEx manufactured, recycled, and rented wooden pallets from its 71 facilities in 23 states and seven Canadian provinces, while IFCO supplied 50 million collapsible, reusable plastic produce containers to 15,000 supermarkets in 15 European countries. The combined company, named IFCO Systems, allowed PalEx to expand its pallet business into Europe and IFCO to expand its plastic container business into North America, setting the foundation for the combined firm to expand into Latin America and Asia. In 2004, the former PalEx business was operating as IFCO System North America.

Rounding out the top three industry leaders were Love Box Company Inc. of Wichita, Kansas, with 2002 sales of $175 million and 1,500 employees, followed by TRAK International Inc. of Port Washington, Wisconsin, with estimated sales of $100 million in 2002.

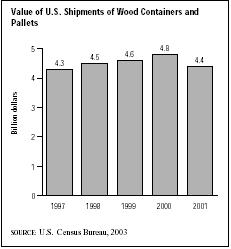

According to the U.S. Census Bureau, more than 2,000 establishments operated in this category at the turn of the twenty-first century. Industry-wide employment totaled 51,311 workers receiving a payroll of $1.12 billion; 43,817 of these employees worked in production, putting in more than 81 million hours to earn wages of almost $793 million. Overall shipments for the industry were valued at almost $4.4 billion in 2001.

The vast majority of pallets and skids produced in the United States were made of wood. The remaining pallets were made of wood composite, cardboard/corrugated, metal, plastic, or other materials. In 2000, about 429 million new wood pallets and skids were manufactured in the United States. Used and/or repaired pallets added an additional 233 million to this total. The per firm annual production of pallets in the United States doubled between 1980 and 1995. The average daily production of new and used wood pallets per firm, per shift, totaled 1,337 in 2000. The industry was operating at roughly 58 percent of its capacity that year.

Computers have had a major impact on pallet design since about 1980. In the mid-1990s, a computer-assisted

Pallet Design System enabled manufacturers to better analyze the pallet needs of a particular product and to build pallets specifically tailored for that product. For example, a company dealing in a fairly light commodity could save money using pallets made from softer, less expensive wood.

By the 1990s the pallet industry had incorporated recycling. More than 40 percent of all firms used some recycled pallets during production in 1995, with an average of 131,500 recycled pallets used annually per firm. Recycling became a more common low-cost option for wood pallet companies as competition from nonwood pallet producers increased. The wood pallet industry responded to this challenge with the development of "enhanced pallets," which are more resistant to fire and rot than conventional pallets. There was also a trend toward producing multiple-use pallets, which could be leased by customers and returned when worn out. Fueling the growth of recycled pallets in the early 2000s was an increase in raw materials costs. In 2003 alone, hardwood pallet raw materials costs jumped 11 percent, pushing hardwood pallet prices up 4 percent.

Several trends were expected to affect the pallet industry in coming years. In addition to growth in recycling and leasing pallets, and the use of nonwood materials, producers will continue automating the design and manufacturing process. Consolidation, like the PalExIFCO merger, should also continue. A shrinking labor force combined with future Occupational Safety and Health Administration (OSHA) and environmental legislation were also expected to affect the industry, as well as the chance of reduced access to federal forest lands.

Further Reading

U.S. Census Bureau. "Statistics for Industry Groups and Industries: 2000." February 2002. Available from http://www.census.gov/prod/2002pubs/m00as-1.pdf .

——. "Value of Shipment for Product Classes: 2001 and Earlier Years." December 2002. Available from http://www.census.gov/prod/2003pubs/m01as-2.pdf .

U.S. Department of Agriculture. "Recycling Behind Most Growth in Pallet Production." 2002. Available from http://www.srs.fs.usda.gov/pubs/viewpub.jsp?index=5094 .

Comment about this article, ask questions, or add new information about this topic: