SIC 1475

PHOSPHATE ROCK

This category covers establishments primarily engaged in mining, milling, drying, calcining, sintering (heating without melting), or otherwise preparing phosphate rock, including apatite.

NAICS Code(s)

212392 (Phosphate Rock Mining)

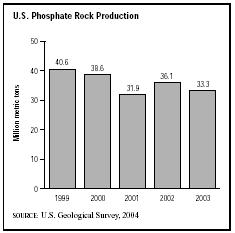

In 2003, nine U.S. firms in four states mined phosphate rock ore, compared to 20 firms in 1997. In 2003 mines produced an estimated 33.3 million metric tons of phosphate rock, with a value of $895 million f.o.b. mine. The United States is the world's leading producer and consumer of phosphate rock, over 90 percent of which is used to produce chemical fertilizers and animal feed supplements. In 2003, it accounted for about one-fourth of total global production, down from one-third in the late 1990s. The states of Florida and North Carolina produced 85 percent of the total U.S. phosphate rock output, with Idaho and Utah contributing the rest. After growing for seven consecutive years in the late 1990s, phosphate rock production in the United States began to wane, plunging from 40.6 million metric tons in 1999 to 31.9 million metric tons, its lowest point in 30 years, in 2001. Although production rebounded somewhat to 36.1 million metric tons in 2002, it dipped to 33.3 million metric tons in 2003. This decline was due in large part to reduced exports to China, where the market for diammonium phosphate (DAP) had weakened considerably. Between 2000 and 2001, U.S. phosphate rock exports had plunged from 299,000 metric tons to 9,000 metric tons. By 2003, exports were down to a mere 5,000 metric tons.

The mineral phosphate took over 150 natural forms and was required by all plant and animal life for existence. All of the U.S. production of phosphate minerals—and 90 percent of worldwide production—was the sedimentary phosphate rock known as phosphorite, which was largely comprised of carbonite apatite. The phosphate rock mining and preparation industry produced the phosphorus that comprised one of three primary ingredients of agricultural fertilizers.

A substantial percentage of mined low-grade phosphate was used in an untreated state as soil fertilizer. This natural phosphate released its phosphorus content into soils relatively slowly, however, so greater volumes had to be extracted to achieve the same effects as more concentrated processed phosphate fertilizers. Common forms of treated or processed phosphate compounds include phosphoric acid, triple superphosphate, ammonium phosphate, and superphosphate. The harvesting of one ton of wheat required the application of about 18 pounds of phosphoric acid fertilizer, which was usually applied to the soil through irrigation water.

In addition to its use as a fertilizer, phosphate rock provided orthophosphoric acid and elemental phosphorus, which were used in applications such as leavening agents, photographic chemicals, water softeners, oil refining, beverages, insecticides, ceramics, detergents, plasticizing chemicals, and scouring powders. Phosphate rock was also widely used as a source of fluorine for making plastics and resins, laboratory dies, refrigerants, solvents, lubricants, and aerosol propellants. Phosphorus also played a role in the production of explosives and fireworks and in steel production. Phosphate rock found in Idaho contained vanadium, which was used as a bonding agent in the manufacture of titanium steel, as a stabilizing agent in steel production, and as a rust-resistant element in high-speed tools.

The extremely high costs of acquiring and holding mineral properties, conducting feasibility studies and exploration operations, purchasing and maintaining mining equipment, and developing and operating the mines themselves, made the mining industry one of the most capital-intensive in the United States. Historically, the majority of phosphate rock mined in the United States was extracted from open pits, but the number of underground mining operations gradually increased. Open pit mining was performed by large excavating machines, which stripped the "overburden" (nonproductive overlay) and removed it from the site. A typical operation involved washing the mined phosphate with a hydraulic jet and then pumping it in liquefied "slurry" form to a washing plant. The phosphate was then mechanically graded by size, concentrated, and dried.

Phosphate mining began in Idaho in 1906 and in Montana in 1920. The use of phosphate fertilizers in sugar beet fields first occurred in the western United States in the mid-1930s. The production of phosphate rock grew rapidly during World War II and reached 10.7 million metric tons by 1950. And by 1964, 23.3 million metric tons were produced in the United States alone. Although worldwide consumption of phosphate fertilizers increased from the 1970s to the 1990s, its rate of growth steadily fell off, from 5 percent a year to 2 percent or lower by the mid-1990s. The International Fertilizer Industry Association predicts phosphate fertilizer consumption to grow an average of 2.7 percent between 2003 and 2008.

One of the most important trends in the U.S. phosphate mining industry in the late 1990s and early 2000s was industry consolidation. Grain surpluses, an excess supply of phosphate fertilizer worldwide, and depressed prices between 1981 and 1986 forced North American phosphate producers to begin seeking greater efficiencies. For example, Potash Corporation of Saskatchewan (PCS) bought two phosphate mines and chemical plants in Florida to complement its existing phosphate complex in North Carolina. The 1996 purchase gave PCS control of approximately 39 percent of U.S. phosphate reserves, the largest in the industry, and made PCS the third-largest phosphate producer in the world. Similar consolidation activities by U.S. phosphate mining firms—such as the merger of IMC Global and Vigoro—created significant economies of scale within the industry. Several idle mines were purchased and reopened. IMC Global paid $16 million to Agrifos Fertilizer LLC for its Florida-based Nichols Mine, including 6.6 million metric tons of phosphate rock reserves, in 2002. As of 2004, the firm operated five phosphate mines in Florida.

Industry firms also turned to advanced mineral processing technologies such as the WPPA manufacturing process. As a result, coupled with increased global demand for phosphate-based agricultural fertilizer, the out-look for the U.S. phosphate mining industry in the early 2000s was favorable. Asia, Oceania, and South America are all expected to see significant increases in phosphate consumption, and U.S. exports to those areas are forecasted to increase, according to the U.S. Geological Survey.

Further Reading

Jasinski, Stephen M. "Phosphate Rock." U.S. Geological Survey Minerals Yearbook. Washington, DC: U.S. Geological Survey, 2002. Available from http://minerals.er.usgs.gov/minerals .

"Phosphate Rock." Mineral Commodity Summaries. Washington, DC: United States Geological Survey, January 2004. Available from http://minerals.er.usgs.gov/minerals .

Comment about this article, ask questions, or add new information about this topic: