SIC 2655

FIBER CANS, TUBES, DRUMS AND SIMILAR PRODUCTS

Establishments in this industry are primarily engaged in manufacturing fiber cans, tubes, drums, cones, and similar products from purchased paperboard. These products can be made with or without metal ends. This industry segment produces a wide variety of products, including paper fiber bottles, fiber bobbins, composite cans, all-fiber cans, fiber drums (metal-end or all fiber), fiber cores, mailing cases and tubes, and tubes for chemical and electrical use.

NAICS Code(s)

322214 (Fiber Can, Tube, Drum, and Similar Products Manufacturing)

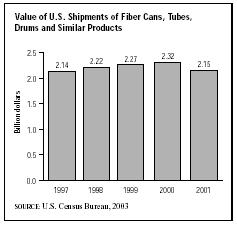

Fiber can and drum manufacturing is a mature industry, with growth at or below the rate of increase in the U.S. gross domestic product (GDP). From 1984 to 1997, the value of this industry's product shipments increased roughly 35 percent, from $1.69 billion to $2.14 billion. With an annualized growth rate of 2.7 percent, this industry ranked among the slower growing paper products industries, but was still close to matching the country's average growth in GDP. However, after growing to $2.32 billion in 2000, the value of shipments in 2001 declined to $2.15 billion. This decrease reflected a general economic downturn in the United States.

The number of establishments in the industry was roughly 275 in the early 2000s, down from 301 in 1992. In 2000, this industry employed 11,378 people with a total payroll of $381.2 million (compared with 13,000 people in 1992). Of that 2000 total, 9,614 were production workers who put in 20.8 million hours for wages of $287.1 million, an hourly average of $13.80.

The manufacture of fiber cans, tubes, and drums is concentrated east of the Mississippi River. The top three producing regions, in terms of total shipments, are the north central, the southeast/mid-Atlantic, and the northeastern regions of the United States. In the early 2000s, Georgia was the leading producer of fiber cans and drums, followed by Ohio, Wisconsin, and North Carolina.

Fiber cans, tubes, and similar products are, by far, the largest category of products produced by this industry, accounting for $1.76 billion of the industry value of shipments in 2001. Paperboard fiber drums, a larger-sized product, accounted for $347.2 million of total fiber cans, drums, and similar product shipments in 2001. Fiber cans, tubes, drums, and similar products not specified by kind accounted for $42.6 million.

Paper and paperboard (not including boxes and containers) represent the single largest category of materials used by the fiber can, tube, and drum industry. Metal closures and crowns for containers claim the next largest share of materials costs, followed by sheet steel and strip and glues and adhesives. The total cost of materials for the industry in 2001 was $1.4 billion, down from $1.42 billion in 2000.

Like other paper product producers, the makers of fiber cans, tubes, and drums have been using more recycled paperboard and less virgin paperboard in order to

satisfy end user demands. In the late 1990s and early 2000s, this industry appeared to benefit from the desire by consumers and the government to use more products made from recycled materials or materials that were more recyclable than competing products. This environmental factor was a distinct advantage for industry manufacturers as many competing products are made from plastic, which is perceived to be a less recyclable product.

The paper industry is a good customer as well as a supplier for the fiber can, tube, and drum industry. Many mills use heavy-duty fiber cores to wind their paper and paperboard rolls. These cores are either shipped in long lengths and cut at the mill or pre-cut by the core manufacturer. This market shows little sign of moving toward alternative products, such as steel cores.

The fiber drum has seen its market share decline as many industrial users are trying to eliminate the use of disposable containers. For example, for regulatory reasons, the chemical industry is moving away from using drums of any kind, including fiber or metal. Instead, they are using more portable chemical feed containers that are dropped off by the chemical manufacturer and then picked up to be reused when empty.

Some of the industry leaders in this category are integrated manufacturers, in that they produce fiber cans, drums, and tubes, as well as the paperboard from which they are made. Other fiber can, tube, and drum manufacturers are independent converters of purchased paperboard. One of the leading companies in this industry, Sonoco Products Co. of Hartsville, South Carolina, is an integrated producer. Sonoco posted sales of $2.75 billion in 2003 and employed 15,200 workers. Other leaders in this industry include Delaware, Ohio-based Greif Inc., formerly known as Greif Bros. Corporation, which secured sales of $1.91 billion in 2003 and employed 9,800 workers; Star Paper Tube Inc. of Rock Hill, South Carolina; Anvil Cases Inc. of Hacienda Heights, California; and Niemand Industries Inc. of Marion, Alabama.

Further Reading

U.S. Census Bureau. "Statistics for Industry Groups and Industries: 2000." February 2002. Available from http://www.census.gov/prod/2002pubs/m00as-1.pdf .

——. "Value of Shipment for Product Classes: 2001 and Earlier Years." December 2002. Available from http://www.census.gov/prod/2003pubs/m01as-2.pdf .

Comment about this article, ask questions, or add new information about this topic: