SIC 2048

PREPARED FEEDS AND FEED INGREDIENTS FOR ANIMALS AND FOWLS, EXCEPT DOGS AND

CATS

This classification covers establishments primarily engaged in manufacturing prepared feeds, feed ingredients, and adjuncts for animals and fowls, except dogs and cats. Included in this industry are poultry and livestock feed and feed ingredients such as alfalfa meal, feed supplements, and feed concentrates and pre-mixes. Also included are establishments primarily engaged in slaughtering animals for animal feed. Establishments primarily engaged in slaughtering animals for human consumption are classified in SIC 2011: Meat Packing Plants, SIC 2013: Sausages and Other Prepared Meat Products, and SIC 2015: Poultry Slaughtering and Processing. Establishments primarily engaged in manufacturing cat and dog foods are classified in SIC 2047: Dog and Cat Food.

NAICS Code(s)

311611 (Animal (except Poultry) Slaughtering)

311119 (Other Animal Food Manufacturing)

Industry Snapshot

Feed is by far the largest input cost of producing food and fiber of animal origin, exceeding even the initial cost of the animals themselves. The cost of feed represents 50 to 70 percent of the cost of producing meat, milk, and eggs at the farm level. For instance, the United States Department of Agriculture (USDA) calculates that it requires 88 pounds of feed to produce 100 pounds of milk; 9,523 pounds of feed to produce a steer; 1,273 pounds to produce a lamb; 50 pounds of feed for 100 eggs; 261 pounds of feed to produce 100 pounds of poultry; and 629 pounds of feed for 100 pounds of pork. In the case of grass-eating livestock such as cattle and sheep, a great deal of their nutrition may come from foraging pasture land, but the latter stages of their lives often require significant portions of prepared feeds. With poultry and hogs, however, nourishment is supplied primarily through prepared feed mixes.

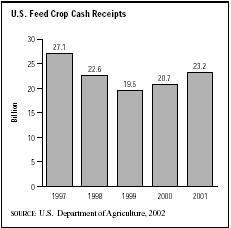

According to the American Feed Industry Association, as much as $20 billion worth of feed ingredients are purchased each year. These products range from grain mixes to orange rinds to beet pulps. The feed industry is one of the most competitive businesses in the agricultural sector and is by far the largest purchaser of U.S. corn, feed grains, and soybean meal. Tens of thousands of farmers with feed mills on their own farms are able to compete with huge conglomerates with national distribution. Feed crops generated $23.2 billion in cash receipts on U.S. farms in 2001. At the same time, farmers spent a total of $24.5 billion on feed that year.

Organization and Structure

Owning a feed mill is a capital-intensive operation. Many modern feed mills increasingly rely on computer technology; human hands rarely touch the feed ingredients. Not only can the feed mill itself be a multimillion dollar investment—with attendant costs associated with maintaining a competitive position regarding machinery—but the feed manufacturer must also have an expensive commodity inventory on hand at all times. Mill managers attempt to purchase their ingredients up front, often contracting for goods months in advance. To hedge the risks associated with fluctuating grain and commodity prices, many feed manufacturers utilize the option of futures trading. Most feed manufacturers also have a sizable investment in a truck fleet used to deliver bulk feed to dairies, poultry, and swine operations. Virtually all cattle feedlots in the United States, however, prepare their feed on the premises in bulk form. Many poultry processing companies own their own feed mills and sell the feed to contracting

poultry producers who in turn sell their broilers back to the processor.

Retail outlets often will carry only one brand of feed. In return, the feed companies do extensive advertising in the rural press, usually on a regional basis. Another important aspect of the feed industry is the production of sacked feed, which is sold through farm supply stores and feed dealers. This feed is often used for 4-H and Future Farmers of America projects, backyard poultry projects, and for feeding horses and small animals like rabbits and guinea pigs. Although the sacked feed sold in farm supply stores is prepared in the same manner as the feed delivered in bulk form, it is more expensive because of the extra packaging.

Nutritional Experts. More than 150 micro- and macro-ingredients are covered in a guide prepared by the Nutrition Council, which has become the authoritative source for the feed industry. Nutritionists are commonly employed in the feed manufacturing industry to determine the needs of domestic livestock. Animal nutritionists rely heavily on university research and industry publications for information on the chemical properties of various feed ingredients and their use and availability.

The role of the nutritionist is to calculate a ration that fits the nutritional requirements for the least cost. This is known as a "least-cost ration," and is the ultimate goal of all livestock nutritionists. There are thousands of professional nutritionists working for livestock feed suppliers, poultry feed manufacturers, feedlots, and poultry raising operations who spend a great deal of their time determining the needs of each animal during different phases of its productive life cycle. Nutritionists use the most sophisticated computer hardware and software to make these calculations on a daily basis. Nutritionists either are employed in-house or work as consultants.

The job of the feed manufacturer is to buy the commodities and blend them in the feed mill according to the specifications outlined by the nutritionist. There is little room for error because, if the ration is not apportioned correctly, lowered animal production and diminished outward appearance can occur.

Associations. The 1992 merger between the National Feed Ingredients Association (NFIA) and the American Feed Industry Association (AFIA) under the AFIA name brought the entire feed industry under representation by a single organization for the first time since 1909. The membership of the American Feed Industry Association includes companies that manufacture feed to sell, firms that manufacture feed for their own animals, and those that provide equipment, ingredients, services and supplies to feed manufacturers. AFIA headquarters are located in Arlington, Virginia.

One of the primary goals of the AFIA is to represent the interests of the feed industry on federal legislation and regulation. The AFIA meets often with U.S. Food and Drug Administration officials to coordinate such things as mill inspections, manufacturing practices, labeling requirements, feed additives, and the administration of laws and regulations. The AFAI played a leading role in the development of the Uniform State Feed Law and other regulations mandating uniform feed labels.

Current Conditions

According to the USDA, one of the largest expenditures for U.S. farmers in 2001 was feed, accounting for 12.4 percent of total farm production expenditures, which reached $197 billion. In fact, the only expenditure to exceed feed was farm services. Even labor was cheaper than feed for most farms. However, feed expenditures had declined steadily throughout the late 1990s and early 2000s, falling from $26.3 billion in 1998 to $24.5 billion in 2001. The value of feed crops had also declined during the 1990s, but in the early 2000s, cash receipts from feed crops began to climb, increasing from $19.5 billion in 1999 to $23.2 billion in 2001.

The main ingredients used in commercially prepared feed are the feed grains, which include corn, soybeans, sorghum, oats, and barley. Corn production was valued at nearly $25 billion in 2003, while soybean production was valued at $17.5 billion. Roughly 66 percent of sorghum production, which was valued at $965 million in 2003, is used as livestock feed. Approximately 60 percent of barley production, which totaled 227 million bushels and was valued at $765 million in 2003, is used as livestock feed. Annual oat production in 2003 was valued at $218 million.

The sale and manufacture of pre-mixes is an industry within an industry. Pre-mixes are comprised of micro-ingredients such as vitamins, minerals, chemical preservatives, antibiotics, fermentation products, and other essential ingredients that are purchased from pre-mix companies, usually in sacked form, for blending into commercial rations. Because of the availability of these products, a farmer who uses his own grain can formulate his own rations and be assured that his animals are getting the recommended levels of minerals and vitamins.

Industry Leaders

Leading companies involved in prepared feeds production in the early 2000s included ConAgra Inc., an Omaha, Nebraska-based firm; and Cargill, Incorporated, a diversified company that was the nation's top exporter of grain. In 1998 Ralston Purina Company, based in St. Louis, Missouri, formed Agribrands International, Inc. to control its international animal feed and agricultural products division. Agribrands produced feed and other products for livestock in markets outside of the United States and had about 75 facilities operating in 16 countries. In 2001 it was acquired by Cargill.

Other significant industry players included Conti Group Companies, Inc., the world's leading cattle feeder; CHS Inc. (previously known as Cenex Harvest States Cooperative), which was primarily involved in grain trading; and Farmland Industries, Inc., the leading agricultural cooperative in the United States. Farmland was a worldwide exporter of products, such as grain. In May of 2002, however, the firm declared bankruptcy. The following year Smithfield Foods Inc. acquired most of Farmland's assets.

Further Reading

Hoover's Online, 2004. Available from http://www.hoovers.com .

Leake, Linda L. "Sign of the Times." Farm Journal, February 2000. Available from http://www.farmjournal.com .

U.S. Department of Agriculture. Crop Summary. Washington, DC: 2003. Available from http://usda.mannlib.cornell.edu/reports/nassr/price/zcv-bb/cpv10204.txt .

U.S. Department of Agriculture. Track Records of U.S. Crop Production. Washington, DC: 2003. Available from http://usda.mannlib.cornell.edu/data-sets/crops/96120/track03b.htm .

Comment about this article, ask questions, or add new information about this topic: