SIC 2046

WET CORN MILLING

This industry comprises establishments primarily engaged in milling corn or sorghum grain (milo) by the wet process, and producing starch, syrup, oil, sugar, and byproducts, such as gluten feed and meal. Also included in this industry are establishments primarily engaged in manufacturing starch from other vegetable sources, such as potatoes and wheat. Establishments primarily engaged in manufacturing table syrups from corn syrup and other ingredients and those manufacturing starch base dessert powders, are classified in SIC 2099: Food Preparations, Not Elsewhere Classified.

NAICS Code(s)

311221 (Wet Corn Milling)

Also known as corn refining, the wet corn milling industry processes roughly 20 percent of the U.S. corn crop. In 2002 the United States produced 9.01 billion bushels of corn for grain production. The reflected a 5 percent decrease from 2001.

Use of the corn kernel differs by product. Corn starch is used in a variety of industries, including food products, paper, adhesives, textiles, and pharmaceuticals. Starch can also be converted to ethanol. Wet corn millers advocated using ethanol as part of an overall national energy policy. Between 1981 and 1991 drivers around the world traveled almost one trillion miles on fuels made with ethanol blends. Also produced from starch, corn sweeteners—corn syrup, dextrose, and high fructose corn syrup (HFCS)—accounted for more than 55 percent of U.S. sweetener consumption in the early 2000s, according to the Corn Refiners Association. In 2003, an estimated 535 million bushels of corn were used to make HFCS, which since 1980 has been the sweetener of choice for the major U.S. soft drink manufacturers.

Germ is the portion of the kernel from which a seed would sprout. The germ contains oils used to make margarine, mayonnaise, salad dressings, and shortening. Other portions of the corn kernel are made up of protein and are used to produce corn gluten feed and corn gluten meal for animals and poultry.

Wet corn milling in the United States grew by more than 50 percent from 1987 to 1995, expanding shipments from $4.8 billion in 1987 to $7.5 billion in 1995. Performance in 1995 showed a 17 percent increase in value over shipments in 1992, when the industry totaled $6.4 billion in shipments. Growth in the 1990s was not steady, however, with 1993 actually showing a decrease of 3.8 percent in the value of wet corn milling shipments from 1992. Shipment values, which totaled $7.1 billion in 1997, declined to $6.1 billion in 2001.

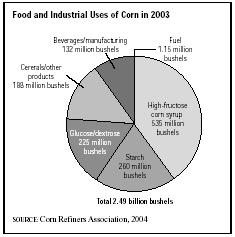

According to the Corn Refiners Association, fuel accounted for 1.15 million bushels of the total 2.49 million bushels of corn used for food and industrial products in 2003. HFCS was the next largest use, accounting for 535 million bushels. Roughly 260 million bushels of corn were used to make starch; 225 million bushels of corn were used to make glucose and dextrose; 188 million bushels were used to make cereals and other products; and 132 bushels were used for beverages and manufacturing in 2003.

Approximately 50 establishments operated in the industry in the early 2000s. Such multibillion dollar agribusiness concerns as Archer Daniels Midland Company (ADM) of Decatur, Illinois; Cargill, Incorporated of Minneapolis, Minnesota; and Corn Products International Inc. of Bedford Park, Illinois, were among the leading producers. ADM, which operated four wet corn milling facilities, employed 26,000 workers and generated sales of $30.7 billion in 2003. Cargill, Inc., the largest privately owned company in the United States, employed more than 98,000 people worldwide and topped $59.8 billion in sales in 2003. Corn Products International posted sales of $2.1 billion in 2003, approximately 15 percent of which was attributed to its corn refining business. Corn Products is a spinoff of CPC International.

Employment fluctuated considerably during the 1980s and 1990s, varying from a low of 8,300 in 1989 to a high of 9,700 in 1991. The industry's workforce was roughly 10,000 people in the early 2000s, with Iowa, Illinois, and Indiana providing more than 70 percent of the industry's labor.

In 2002 researchers at the Agricultural Research Service Conversion Science and Engineering Research Unit of the U.S. Department of Agriculture applied for a patent for a new corn refining method. By using protease inhibitors to break down starch and protein, refiners will be able to reduce the time it takes to soak corn kernels in sulfur dioxide from 24 hours to just six hours. According to a September 2002 issue of Agricultural Research, "After 100 years of doing it the same way, corn refiners will soon have another option that can potentially lower costs and shorten the time needed to produce starch, oil, and other co-products."

Further Reading

Corn Refiners Association. Statistics, 2004. Available from http://www.corn.org/statistics.htm .

Johnston, David B. "Getting More Out of Corn—More Economically." Agricultural Research, September 2002.

U.S. Census Bureau. "Value of Shipment for Product Classes: 2001 and Earlier Years." December 2002. Available from http://www.census.gov/prod/2003pubs/m01as-2.pdf .

U.S. Department of Agriculture. Economic Research Service. Feed Outlook, 12 March 2004. Available from http://www.ers.usda.gov .

U.S. Department of Agriculture. National Agricultural Statistics Service. Statistical Highlights 1998-1999: Farm Economics, 2000. Available from http://www.usda.gov/nass .

Comment about this article, ask questions, or add new information about this topic: