SIC 1423

CRUSHED AND BROKEN GRANITE

This classification covers establishments primarily engaged in mining or quarrying crushed and broken granite, including related rocks, such as gneiss, syenite, and diorite.

NAICS Code(s)

212313 (Crushed and Broken Limestone Mining and Quarrying)

The top crushed and broken granite producer in the early 2000s was the family-owned Luck Stone Corp. of Richmond, Virginia, with more than 900 employees in 2004. The company, founded in 1923 and now run by the third generation of the Luck family, was the twelfth

largest producer of crushed stone in the United States, operating nearly 20 crushed stone and sand-and-gravel plants, and eight retail stores in Virginia and North Carolina. Its automated, noise-controlled crushers had the capacity to produce and ship over 600,000 tons of stone daily, as compared to its 1923 capacity of 100 tons produced manually by men with sledgehammers, loading mule-drawn carts by hand. Retail stores, part of the Architectural Stone division, offered crushed stone to construction professionals as well as the general public for diverse uses such as in fireplaces and garden pathways.

The industry is composed primarily of small independent operators, with a few large companies producing a significant percent of total granite output. Approximately 150 companies operate 365 granite quarries in 34 states. Leading states include Georgia, North Carolina, Virginia, South Carolina, and Arkansas. Together, these five states make up nearly three-fourths of total production.

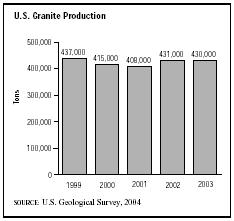

A small but healthy segment of the U.S. crushed stone industry, crushed granite accounted for approximately 15 percent of U.S. production as of 2003. That year, the United States produced nearly 430,000 tons, down from 437,000 tons in 1999. In general, granite production growth and prices have exceeded the average for crushed stone in the early 2000s. As with most types of crushed stone, the majority of crushed granite—roughly 56 percent—is used as construction aggregate. Leading importers of granite include Italy, which accounts for 41 percent of granite imports; Brazil, which accounts for 17 percent; India, which accounts for 13 percent, and Canada, which accounts for 11 percent. Exports of granite declined from 166,000 tons in 1999 to 140,000 tons in 2003.

Civil engineers found granite as early as 1871 along the main coastal line of the Southern Pacific railroad. As track was laid throughout California, engineers discovered that granite was the perfect ballast material for railroad beds. With the inception of automated, steam-powered crushers, the mining and production of granite improved significantly.

When crushed to powder, tiny fragments of separate substances can be picked out of granite. These secondary or compositional particles include quartz, feldspar, and mica. As the most common igneous rock in the earth's crust, granite has been mined voluminously for decades.

The introduction of giant, mobile primary crushers in mining operations at granite quarries unleashed enormous production and profit potential. Other recent technological innovations used in granite mining include conveyors that move rock from the primary crusher to wash plants and secondary crushers; state-of-the-art, computer-controlled automated trucks and rail car loading systems; and the complete control and monitoring of all quarry operations by large computer systems.

Further Reading

Barksdale, Richard D., ed. The Aggregate Handbook. Washington DC: National Stone Association.

Infotrac Company Profiles, 20 January 2000. Available from http://web5.infotrac.galegroup.com .

U.S. Geological Survey. Mineral Commodity Summaries, January 2004. Available from http://minerals.usgs.gov/minerals/pubs/mcs/2004/mcs2004.pdf .

Comment about this article, ask questions, or add new information about this topic: