Aerospace Supplier

BUSINESS PLAN

FLATLAND MANUFACTURING, INC.

Principals

Mr. Jon Jones Ms. Mary Smith

Mr. Doug Douglas

Prepared with the assistance of

Tennessee Small Business Development Center

College of Business

East Tennessee State University

P.O. Box 70,698

Johnson City, TN 37614-0698

(615)929-5630

- DESCRIPTION OF THE COMPANY

- MARKET FACTORS

- OWNERSHIP AND MANAGEMENT

- IMPLEMENTATION PLAN

- PERSONNEL POLICIES

- MARKETING PLAN

- PRE-OPENING SCHEDULE OF EVENTS

- FINANCIAL INFORMATION

- STRENGTHS AND WEAKNESSES

- EXPANSION

- SUPPORTING DOCUMENTS

DESCRIPTION OF COMPANY

This is an expanding company created for the purpose of owning and operating enterprises that manufacture gizmos and gadgets for the aerospace industry.

The firm was established in 1982 as a sole proprietorship by Mr. Jon Jones. The business was operated for three years out of Mr. Jones' garage on Q Street, Flatland, Kansas. During this period, the business' revenue grew at an annual rate of 27 percent. In March of 1984, Mr. Jones merged his business with a primary raw materials supplier. This firm was owned by Ms. Mary Smith, located in Smithville, Arkansas. A partnership was formed and Mr. Jones moved his manufacturing operation to Smithville. The partnership existed from this time through June 1989. The partnership continued to show moderate sales increases, but significantly better net income increases due to economies of scale that the merger created. The owners knew that additional revenue could be generated from expanding government contracts. In 1989, Mr. Douglas joined the firm as a principal and government contract specialist. The partnership was dissolved, a corporation was established and the plant was moved to Tennessee. Mr. Jones and Ms. Smith each own 40 percent of the stock and Mr. Douglas owns the remaining 20 percent.

As a result of Mr. Douglas' knowledge of government contracting procedures, revenue increased 253 percent annually until 1991. Since that time sales growth is approximately 23 percent. Total annual revenue for 1991 was $9,600,000.

Services and Products

The firm's primary products are electrical components for military aircraft. The descriptions of these component parts are classified Top Secret by the Department of Defense, and therefore cannot be identified. Additional component parts are manufactured for the domestic aircraft industry. These components are sold directly to the aircraft manufacturers. The firm also makes aline of "after-market" avionics for the private pilot.

As a manufacturer, we have no local competition. Our primary competitors are located throughout the United States. We face global competition for the aircraft after-market industry.

Location

The business is expanding to new facilities located in the newly developing Tri-state Industrial Park. The facility will include 10,000 square feet of manufacturing space, 5,000 square feet of office complex to include drafting and graphic arts, and 250,000 square feet of warehousing space. The facility is located on 1,000 acres with rail access. This site was selected due to its zoning which permits a heliport and automatic weapons firing range.

MARKET FACTORS

The information in this section is derived from the Marketing Questionnaire, prepared by Smith Brothers. Please refer to the Support Documents section of this plan for details about obtaining the complete analysis.

Market Need for the Business

There are currently two major aircraft manufacturers in the United States. Total component part sales to these firms accounts for a total of $25,000,000 in purchases of the parts and components that we manufacture. As the air fleet ages, the demand for replacement parts increases. This market is expected to top $50,000,000 by the year 2000.

The end of the "Cold War", and the resulting "Peace Dividend" has dropped revenue from the Department of Defense contracts by 60 percent. However, some of this funding is being shifted to NASA for the development of the space station project.

This business is within a 50 mile radius of a major regional airport and 6 smaller local airports. There are about 700 locally owned and registered private aircraft. Thirty percent of the firm's manufactured products are related to the aircraft after-market. Approximately 150,000 square feet of the warehouse facility will be devoted to a Manufacturers Outlet Mall for aircraft enthusiasts.

Local Market Characteristics

Economic

Local air traffic at the Tri-state airport has been steadily increasing at a rate of 13 percent per year. Plans are in the works to expand the facility to two runways and to add two additional air carriers. This being done, air traffic should increase by another 27 percent. These additions would permit the establishment of a secondary air maintenance facility at the airport. This would increase the local demand for this firm's products.

Demographics

Two local schools, one a community college, the other adult vocational education, have added private pilot training to their curriculum. This will increase the flight hours logged on existing aircraft and increase the sales of new aircraft. Both of these situations will increase the demand for the firm's replacement parts and after-market components.

OWNERSHIP AND MANAGEMENT

This firm is owned by Mr. Jon Jones (40%), Ms. Mary Smith (40%), and Mr. Doug Douglas (20%). Mr. Jones is the CEO and president. Ms. Smith is the secretary treasurer. Mr. Douglas handles government bidding and all estimating functions. The firm has two outside directors: Mr. Black and Ms. White. These directors have no ownership interest. They were selected due to their knowledge of business finance (Mr. Black) and corporate management (Ms. White). Mr. Black and Ms. White act as arbitrators in case of disputes. Each of the five directors have one vote on corporate matters. The outside directors, in accordance with corporate by-laws, are selected by unanimous vote of the stockholders.

Mr. Jones also oversees production operations as the firm's general manager. Ms. Smith is the firms purchasing director. She manages the daily business operations. Mr. Douglas works closely with the firm's CPA firm, Banks, Yur, Monnie & Runns Associates, in the area of cost accounting and pricing.

Personal financial statements and resumes of the three principals are available upon request.

IMPLEMENTATION PLAN

Facility

The newly constructed facility will consist of 265,000 square feet of office, manufacturing, warehouse and retail space. Information concerning preliminary construction plans is located in the Supporting Documents section. An environmental impact assessment has been conducted and the property received a cleanbill of health from Greene Fields, Consulting Environmental Engineer, 1224 E St., Getty, TN 37290. The analysis and results are available from this office upon request.

The building is designed in accordance with standards set forth in the Americans With Disabilities Act and other laws and regulations pertinent to government contractors, local zoning requirements and pollution (air, noise, and water) abatement programs.

Equipment

The firm uses a mixture of high technology equipment and routine machine tools. A list of equipment to be purchased is available upon request. Approximately $850,000 of equipment has been provided by the Department of Defense. This equipment remains the property of the U.S. Government and is not pledged as collateral for this loan. The firm currently owns $250,000 in fully depreciated, paid-in-full equipment. A list of this equipment is also available upon request.

Inventory

The firm maintains an approximate 45 day supply of raw materials inventory for manufactured military aircraft component parts. These parts are manufactured under the Just-In-Time inventory system of the prime contractor. A 60 day supply of raw materials is maintained to comply with the Just-In-Time inventory system of the major airline manufacturers. The firm maintains an approximate 15 day finished goods inventory for the aircraft after-market.

Raw materials inventory is accounted for using the LIFO method, while finished goods inventory is accounted for using the FIFO method. The firm uses a fully integrated accounting package which permits a perpetual inventory. A physical inventory is taken at the end of each government contract, with appropriate adjustments made at that time. For non-government contract inventory items, a physical inventory is taken semi-annually in April and October.

Quality Control

The firm is implementing ISO 9000 standards for all non-government work. For government contracts, Military Inspection Requirements MIL-I-45208A and Military Quality Program Requirements MIL-Q-9858A continue to apply as quality standards.

The firm has implemented a Quality Control/Zero Defects program. Floor employees are provided financial and non-financial incentives for exceeding goals set for reducing rejects and re-works. Administrative employees are offered cost reduction incentives equal to 25 percent of cost savings for suggestions resulting in savings of $25,000 or more.

Labor Force

Employment at this firm falls into five categories. Table 1 shows current employment and the three year projection of employment increases due to expansion. The source of skilled employees is area high school vocational education and community college graduates from two-year programs. Professional and technical employees require a four year college degree. Local colleges and universities offer some, but not all, of the required degree programs. All educational specialties are to be found in Tennessee's university system.

| Employment Trends | ||||

| Employment Category | Current | Year1 | Year2 | Year3 |

| Management | 2 | 2 | 2 | 3 |

| Professional/Technical | 5 | 6 | 6 | 8 |

| Skilled | 15 | 20 | 23 | 27 |

| Unskilled | 27 | 25 | 23 | 21 |

| Clerical | 3 | 3 | 4 | 4 |

| Total | 52 | 56 | 58 | 63 |

Training

This firm uses a variety of training methods. New skilled and unskilled laborers are trained as needed using Job Training Partnership Act programs. These training programs are available through the Alliance For Business and Training. This includes both classroom training and OJT. Newly hired professional and technical employees are tested at the time of employment with the expectation that they are fully trained and competent at the time of their employment.

The firm also offers a variety of continuing skill improvement programs. Managerial, professional, and technical employees are expected to attend at least one seminar, conference, or continuing education program per year. A tuition reimbursement program is offered to all employees. The firm pays 100 percent of tuition for employees receiving an "A", 80 percent for a "B", 50 percent for a "C", and 20 percent for a "D". No reimbursement is received for a failing grade.

PERSONNEL POLICIES

Employees will be paid at a competitive market rate.

Compensation

Management personnel will be paid a base salary, plus an annual bonus based on the net pre-tax profit of the firm, as established by the Board of Directors.

Skilled, unskilled, and clerical personnel will receive an hourly wage with time and a half for all hours over 40 hours per week.

Skilled, unskilled, and clerical employees will receive shift differentials of 10 percent of their hourly wage for second shift and 20 percent of their hourly wage for third shift.

Hours of Operation

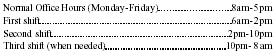

| Normal Office Hours (Monday-Friday) | 8am-5pm |

| First shift | 6am-2pm |

| Second shift | 2pm-10pm |

| Third shift (when needed) | 10pm-8 am |

Holidays

- New Year's Day

- Memorial Day

- July 4th (observed)

- Labor Day

- Opening day of deer season

- Thanksgiving Day

- Christmas Eve

- Christmas Day

Vacation and Other Time Off

Sick leave Sick leave is accrued at a rate of one half day per month. It shall be accumulated during the entire length of employment. Sick leave is a benefit to the employee for illness only, it will not be "cashed out" upon termination of employment. To reduce absenteeism and abuse of the sick leave benefit, employees not using sick leave during a twelve month period ending on their anniversary date will be given two additional days of vacation and a $100 bonus.

Vacation Managerial, professional, and technical employees will receive three weeks vacation per year. Skilled, unskilled, and clerical employees will receive two weeks vacation per year. At 5 years employment, each employee will receive two additional days vacation. At ten years of service, employees will receive an additional three days vacation.

Insurance The firm offers a group major medical policy for all employees. Coverage for the employee's spouse and family is optional and paid by the employee. The firm offers life insurance for managerial, professional, and technical personnel in the amount of one and a half annual base salary. Additional life insurance is available in $5,000 increments to be paid for by the employee. Key person life insurance is carried on the principals, industrial engineer, and chief accountant.

MARKETING PLAN

As a manufacturer, marketing choices are limited. The U.S. Small Business Administration sponsors Government Procurement Marketplace programs in several regions. Knowing the location of the major prime contractors for our products, we participate in these programs seeking additional government contracts. The Commerce Business Daily is used by the our Government Contracting Section to locate new sources of contracts.

We have designated one sales person to serve the private aircraft market. This individual will establish regular calling schedules for our primary customers.

A two-pronged approach will be taken with our aircraft after-market product line. First, a Manufacturers Outlet Mall will be established in our new warehouse facility. Since this is aretail store, "retail advertising" will be undertaken. Second, the firm shall become a member of the American Aircraft Owners Association. Print advertising will be used every quarter in the AAOA's magazine, Fly or Die. The firm will also purchase the membership roster of the AAOA and known flying clubs. These lists will be used to develop direct mail advertising.

A key to the marketing of our products will be the direct involvement of the principals in establishing sound business relationships and the selling of our products.

Pricing of our "retail" products will be competitive. However, we feel that the quality of our products compared to that of our competition demands a 10 percent price premium. Therefore, we shall price our products slightly ahead of the competition.

PRE-OPENING SCHEDULE OFEVENTS

-

November-December

- Review Articles of Incorporation and Corporate By-laws.

- Complete preliminary business plan.

- Select and engage outside professional assistance, CPA, attorney, architect and builder.

- Begin search for suitable site.

-

January

- Execute legal agreement with architect.

- Begin search for financing sources.

- Continue search for site.

-

February

- Finalize plans for the facility.

- Begin preliminary negotiations with the builder.

-

May-June

- Reach agreement with property owner and purchase the site.

- Complete financing plans and prepare loan request.

- Complete negotiations with contractor.

- Initiate discussions with equipment suppliers and manufacturers.

- Begin negotiations to upgrade employee insurance plans.

-

July

- Obtain site approval from city and county.

- Complete detailed business plan and construction plan.

- Submit financing package to lending group.

-

August

- Obtain final financing approval.

- Complete site purchase.

- Begin construction.

FINANCIAL INFORMATION

Financial Pro-Forma Statements

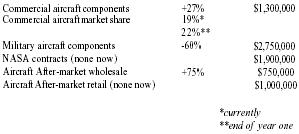

The pro-forma financial statements are based upon the historical financial performance of this firm. Methods of operation make direct comparison to competitor performance unrealistic. Based upon knowledge of the market, the following revenue growth rates are projected.

| *currently | ||

| **end of year one | ||

| Commercial aircraft components | +27% | $1,300,000 |

| Commercial aircraft market share | 19%* | |

| 22%** | ||

| Military aircraft components | −60% | $2,750,000 |

| NASA contracts (none now) | $1,900,000 | |

| Aircraft After-market wholesale | +75% | $750,000 |

| Aircraft After-market retail (none now) | $1,000,000 | |

Other Financial Statements and Projections

Current financial statements and financial projections for the first three years of operation have been prepared. Additionally, annual and monthly balance sheets, historical financial statments, and a break even analysis have been prepared. These documents are available from Banks, Yur, Monnie, & Runns Associates, 293 Adams Rd., Springhill, TN 37998.

STRENGTHS AND WEAKNESSES

Strengths

This firm has many strengths. Chief among them is the varied backgrounds of the principals. Each owner has at least 15 years experience in this industry. The skills and backgrounds of the principals are also varied. One has 25 years manufacturing experience; one has 22 years government procurement experience; and the third 15 years experience in purchasing and materials management.

Our dedication to our work force through established training and financial incentive programs insures that we have a productive and efficient work force.

Weaknesses

The main weakness of this firm is the market in which it operates. Our main contracts are "political footballs." Defense contracts are subject to sudden cancellation. NASA contracts have, in the past, been canceled without advanced warning. These are extremely profitable contracts, but unstable. As a result, our firm is limiting government contracts to no more than one-third of our production capacity. The remaining capacity will provide for a break-even operation until such time as additional contracts can be secured.

EXPANSION

This firm is always looking for ways to expand its revenue and market share within the existing market. Plans are being formulated to add a catalog to its retail operation. This will permit us to expand the sales territory of our after-market products to a national level. Once established, consideration will be given to international distribution of the catalog.

There are similarities in the production of avionic electronics to high quality consumer electronics. This firm is looking at several possibilities at this time. The company has sixty percent of the equipment needed to manufacture High Definition Television (HDTV) components. This firm has not ruled out the possibility of further mergers and acquisitions to enter this market.

SUPPORTING DOCUMENTS

Marketing Questionnaire

To obtain the comprehensive analysis and results of the Marketing Questionnaire, please contact Jerold Smith, of Smith Brothers, at 728 Downy St., Suite 59A, Springhill, TN 37987. The questionnaire offers detailed information concerning company product line, including percentage of total sales and gross margin; primary market; five largest customers, ranked by percentage of sales; customer terms; marketing strategy; industrial information; largest suppliers; market planning.

Construction Plans

Several construction plans have been designed by Athens Architects, Inc., 24 East Ave., Brownie, TN 37984. These drawings are available upon request.

Comment about this article, ask questions, or add new information about this topic: